The valve body acts as the central control unit of your transmission's hydraulic system. It precisely directs the flow of fluid through passages and valves, dictating gear engagement and torque transfer. This complex network orchestrates everything from seamless transitions to powerful acceleration. However, when the valve body falters, the performance suffers. Has your once-smooth gearbox morphed into a clunky monster, with gear changes resembling a tap-dancing rhinoceros? Fear not, fellow motorists, for the culprit might be a malfunctioning transmission valve body. Buckle up as we delve into the technical realm of hydraulics, pinpoint the telltale signs of valve body failure, and explore repair options to get your car back in smooth-shifting harmony.

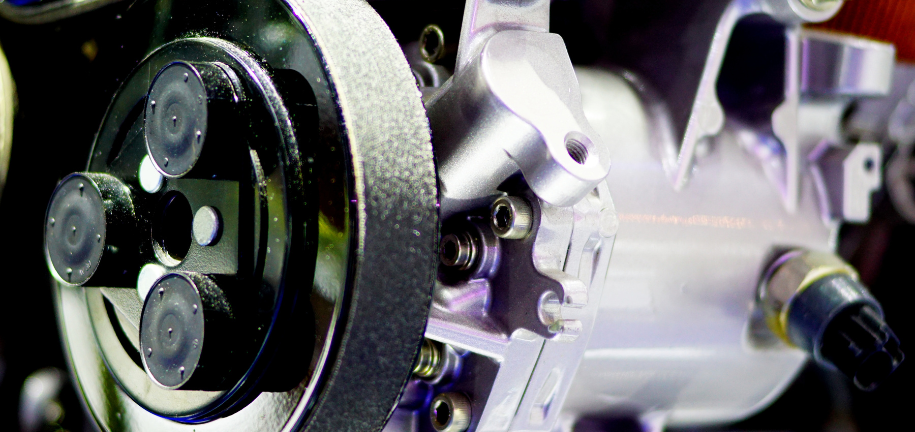

What is the Transmission Valve Body?

The valve body acts as the central control unit of your transmission's hydraulic system. It precisely directs the flow of fluid through passages and valves, dictating gear engagement and torque transfer. This complex network orchestrates everything from seamless transitions to powerful acceleration. However, when the valve body falters, the performance suffers.

Signs of a Failing Valve Body:

- Harsh shifts: Gear changes feel like sudden jolts, throwing passengers around.

- Slipping gears: Engine revs increase without matching acceleration, indicating incomplete gear engagement.

- Delayed shifts: Gear changes take an eternity, leaving you lagging behind traffic lights.

- Check Engine Light: This warning might appear, potentially pointing to valve body issues based on transmission error codes.

- Unusual noises: Whirring or grinding sounds from the transmission suggest internal problems.

Bonus Tip: Regular transmission fluid changes and proper maintenance are key to extending the life of your valve body and keeping your gearbox running smoothly for years to come.

Types of Valve Bodies

There are several types of valve bodies used in various applications, from plumbing and industrial processes to automotive and medical equipment. Here are some common types:

1. Globe Valve: These have a spherical plug that rotates around a vertical axis to control flow. They offer good throttling and shut-off capabilities but have higher pressure drops than some other types. Common in water systems, steam lines, and chemical processing.

2. Gate Valve: These have a flat plate gate that slides up and down to block or allow flow. They have low pressure drops but may not offer as tight shut-off as globe valves. Used in large pipelines, wastewater systems, and power plants.

3. Ball Valve: These have a rotating ball with a hole through it that controls flow. They offer quick, easy operation and good throttling in some designs. Popular in plumbing, gas lines, and food processing.

4. Butterfly Valve: These have a rotating disc inside a circular body that controls flow. They are compact, lightweight, and offer good on-off control but may not have the best throttling capabilities. Used in air handling systems, HVAC applications, and some industrial processes.

5. Diaphragm Valve: These have a flexible diaphragm that moves up and down to control flow. They offer good chemical resistance and isolation but may not be suitable for high pressures or temperatures. Used in pharmaceutical, food, and chemical industries.

6. Check Valve: These allow flow in one direction only and automatically prevent backflow. They are simple and reliable but can add pressure drop to the system. Used in plumbing, pipelines, and various industrial applications.

7. Solenoid Valve: These use an electrically operated solenoid to control a valve. They offer precise control and fast response times but require electrical power and can be more complex than mechanically operated valves. Used in automation systems, medical equipment, and various industrial applications.

8. Pressure Relief Valve: These automatically open to release excess pressure in a system, preventing damage. They are important safety devices used in boilers, pressure vessels, and various industrial processes.

This is not an exhaustive list, and there are many other specialized types of valve bodies available depending on the specific application requirements.

Additionally, valve bodies can be categorized by various factors, such as:

- Material: Brass, stainless steel, cast iron, plastic, etc.

- Port configuration: Two-way, three-way, four-way, etc.

- Actuation method: Manual, pneumatic, hydraulic, electric, etc.

- Pressure rating: Low, medium, high, etc.

- Temperature rating: Low, medium, high, etc.

When choosing a valve body, it is important to consider the specific requirements of your application, including the type of fluid, pressure and temperature conditions, flow rate, and desired control options

What Causes Valve Body Failure?

Several factors can contribute to valve body failure, depending on the type of valve body and its application. Here are some common causes:

- Wear and tear: Over time, moving parts like solenoids and valves can wear out, leading to leaks, sticking, and malfunctioning. Regular maintenance and preventative replacements can help extend the lifespan of a valve body.

- Contamination: Dirt, debris, and corrosion can clog valves and disrupt the flow of fluid, leading to malfunctioning and premature failure. Using clean fluids and proper filtration systems can help prevent contamination.

- Heat and pressure: Extreme temperatures and pressure can damage valve body components, especially if they are not designed for those conditions. Choosing the right materials and designs for the expected operating conditions is crucial.

- Improper lubrication: Insufficient or incorrect lubrication can lead to increased friction and wear on valve components, accelerating their failure. Using the proper type and amount of lubricant is important for smooth operation.

- Electrical issues: For solenoid-operated valves, electrical problems like burnt coils, faulty wiring, or power surges can damage the solenoid and prevent proper valve operation.

- Overuse: Exceeding the design limitations of a valve body in terms of flow rate, pressure, or duty cycle can lead to premature failure. Choosing the right valve body for the application and operating within its specifications is essential.

- Manufacturing defects: In some cases, valve body failure can be caused by manufacturing defects in the materials or components. Choosing reputable manufacturers and performing quality checks can help minimize this risk.

- External factors: Accidents, impacts, or exposure to harsh environments can damage valve bodies and lead to malfunctioning. Implementing proper protection measures can help mitigate these risks.

It's important to note that the specific cause of valve body failure will depend on the type of valve and its application. Identifying the cause is crucial for determining the most appropriate repair or replacement solution.

Here are some additional points to consider:

- Regular maintenance and inspection of valve bodies can help identify potential problems early and prevent them from escalating into major failures.

- Using high-quality components and materials can significantly improve the lifespan and reliability of your valve bodies.

- Consulting with a qualified technician or engineer can help you choose the right valve body for your specific needs and ensure proper installation and operation.

By understanding the causes of valve body failure and taking preventive measures, you can ensure the smooth and reliable operation of your equipment for years to come.

Repair Options and Costs:

Replacing a faulty valve body can be a significant financial commitment. Depending on your car's make, model, and valve body complexity, costs can range from $1,500 to $4,000. Labor adds another layer, as the process involves disassembling and rebuilding the transmission.

Leave it to the Pros:

Unless you're an experienced mechanic with specialized tools and extensive transmission knowledge, this repair is best left to professional hands. DIY attempts can lead to further damage and potentially higher costs. Trust a qualified mechanic to restore your gearbox's smooth operation.

PartsHawk: Your Trusted Pit Crew:

Need replacement valve bodies or transmission parts for your mechanic? PartsHawk offers a comprehensive selection of genuine and aftermarket options for various car models. Their competitive prices, expert advice, and convenient online ordering make the repair process less stressful.

Remember: Ignoring a failing valve body can lead to catastrophic transmission failure, significantly increasing repair costs. Listen to your car's shifting struggles, address the issue promptly, and with PartsHawk as your pit crew, you'll be back on the road with smooth gear changes in no time.